Ever slid a perfectly topped pizza off the peel, only to watch it lose its shape at the last moment? The problem may be the thickness of your peel.

I’ve been there. Just the other week, when visiting family, I prepared a beautiful Neapolitan pizza, ready for the oven. But as I nudged it off my thick wooden peel, it distorted, bunching up at the edges. It was a clear reminder: the thickness of your

The thickness of your

How thick should your pizza peel be?

The short answer is that thinner is better. A thinner peel is going to make it easier to move the pizza onto the peel and off the peel.

When getting a metal peel, you should look for a peel that’s 0.25 cm (0.1 inches) or thinner.

Wooden peels are thicker than metal peels, so when getting a wooden peel, you should look for a peel that’s around 0.5 cm (0.2 inches).

Why pizza peel thickness matters in pizza making

To understand why

There are three main uses for a

- Launching the pizza into the oven

- Moving or rotating the pizza during baking

- Getting the pizza out of the oven

When making Neapolitan pizza, you traditionally prepare the pizza on the countertop before moving it onto the peel and launching it in the oven. The challenge is then to move the pizza over the edge of the peel. This can be challenging if the peel is too thick.

If you work with a wood-fired oven, you typically use a separate type of peel for turning the pizza. There are specialized peels for this purpose, called turning peels. Thin, round, metal peels designed specifically to turn the pizza inside the oven. As a home pizza maker having a turning peel is nice, but not strictly necessary (depending on the size of the oven). So most home pizza chefs would use the same peel for launching and turning.

The last use of a

But let’s dive a bit deeper. In the next section, we will look closer at the different challenges a thick

The challenges of thick pizza peels

Before diving into the specifics of

Let’s explore these challenges to better guide your choice.

Moving the pizza onto the peel

The first challenge when using a thick peel is to get the pizza onto the peel.

With a tick peel, you have an edge you need to drag the pizza over, and the thicker your peel is, the more the pizza will fold as it moves over the edge. This can lead to the misshaping of your pizza and toppings falling off.

When I first got into Neapolitan pizza making, I just couldn’t figure out how to properly move the pizza onto my (thick) wooden peel, so I started topping the pizza on the peel instead. This is a workaround, but not ideal.

Launching the pizza into the oven

When you’re sliding your pizza into the oven, the crucial moment is getting it over the edge of a thick peel. This is where problems often occur.

A thick peel means a higher edge. As your pizza moves over this edge, it can easily get misshapen. You might see it folding or toppings slipping off, leading to a messy oven and burnt toppings.

Turning the pizza during baking

Another challenge you’ll face is rotating the pizza for an even bake. If you’re using a thick peel, sliding it under the pizza for turning will be tricky. The thickness makes it harder to maneuver under the pizza, and if you attempt to do it before the pizza has been set properly, you can fold and ruin the pizza.

Getting the pizza out of the oven

Just like when you’re turning the pizza, retrieving it from the oven with a thick peel can be difficult. The pizza has set when it’s done baking, but it’s still fragile when hot. It’s going to be challenging to slide a thick and bulky peel under the pizza and get it out of the oven without making a mess.

Conclusion: the thinner the peel, the better!

In summary, when considering the thickness of your

It’s important to note that thin peels come with their own set of challenges, particularly concerning the material and durability. Let’s delve into that in the next section.

Types of pizza peels

Pizza peels come in a variety of types. Each type has its own set of characteristics that can affect your pizza-making experience.

The most common types are:

- Wooden pizza peels

- Metal pizza peels

- Perforated pizza peels

- Turning peels

Understanding these differences will help you choose the right peel for your needs.

Wood pizza peels

Wood pizza peels are traditional and widely used. They are great for launching your pizza into the oven thanks to their natural non-stick surface. However, wood peels are thicker, which makes it difficult to turn and retrieve the pizza from the oven.

Metal pizza peels

Metal pizza peels are thinner and more durable. They are easier to maneuver, easier to move the pizza onto, and easier to slide under the pizza for turning and retrieval. However, the dough sticks more to the metal surface, which makes it harder to launch the pizza into the oven

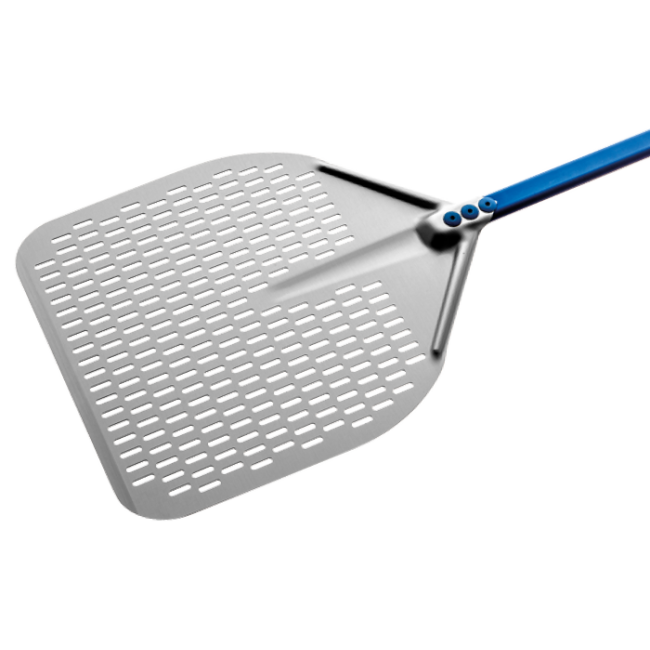

Perforated pizza peels

Perforated pizza peels are an upgraded version of a metal peel. They are also made from metal (typically steel or aluminum), but unlike metal peels, the surface is filled with small holes.

These holes offer two advantages:

- They reduce sticking by providing less surface area for the dough to stick to.

- They allow for the use of more flour, as any excess can easily fall through the holes.

Perforated peels are common in professional settings. They combine the best features of both wood and metal peels. They are thin like metal peels, and the perforated design reduces sticking.

Turning peels

Turning peels are specialized tools designed specifically for rotating the pizza during baking. They are typically made of metal and have a smaller diameter than standard peels, making them ideal for maneuvering and sliding under the pizza in a hot oven. Their thin and sleek design helps in achieving an even bake without disturbing the pizza’s shape.

If you’re baking pizza in a

Comparing the thickness between wood end metal peels

There is no doubt that metal peels are thinner than wooden peels, but how big is the difference? Let’s have a closer look.

Wood peel thickness

Wooden peels typically have a thickness ranging from about 0.5 cm (0.2 inches) to 2 cm (0.78 inches). This range offers a sturdy base but can vary with different types of wood and construction methods.

Wood peel thickness

Metal peels are much thinner, usually between 0.25 cm (0.1 inches) and 0.75 cm (0.3 inches). This slimness makes it much easier to transfer the pizza both in and out of the oven.

Selecting the perfect peel thickness

The thickness of your

The type of oven

The type of oven you use influences the ideal thickness of your

In a home oven or a small

Pizza-making frequency

Your frequency of pizza making plays a role in choosing the right peel thickness. If you bake occasionally, a thicker wood peel might work just fine, offering durability and a classic pizza-making experience. However, for regular pizza enthusiasts or professionals, a thinner metal peel is more practical and efficient.

Pizza-making efficiency

When efficiency is important, a thicker wooden peel increases the risk of mishaps and failed pizzas. It’s faster and easier to move the pizza onto a thin peel, and there is less risk of something going wrong when launching the pizza into the oven.

Balancing budget and quality

While higher-priced peels often offer better quality, you don’t need an expensive peel to make outstanding pizza.

Especially when getting started you can get a well-functioning

Consider how often you’ll use the peel, the type of pizzas you intend to make, and the type of oven you have before making a decision.

Summary of peel thickness selection

In conclusion, selecting the right thickness for your

Pizza peel recommendation for home oven use

For home oven users, especially those with a

I highly recommend the HOMEFAVOR Perforated

This lightweight premium, anodized aluminum peel features a balanced 12x14-inch blade for effortless handling and a perforated surface to reduce sticking.

Over three years and more than a thousand pizzas later, I can attest to its durability and ease of use. Its thin, sturdy design ensures your pizza slides off smoothly, and the perforations are excellent for getting rid of excess flour. It’s a testament that a high-quality peel doesn’t have to break the bank.

Pizza peel recommendation for small pizza ovens

For small pizza ovens like the

The HOMEFAVOR Perforated

This lightweight premium, anodized aluminum peel features a balanced 12x14-inch blade for effortless handling and a perforated surface to reduce sticking.

Additionally, I recommend pairing it with a turning peel for an even bake. You can find my specific turning peel recommendations in my detailed blog post on the subject The Best Pizza Turning Peel. This combination ensures precision and ease in your pizza-making, enhancing the overall experience without a hefty investment.

Pizza peel recommendation for wood-fired ovens

For a wood-fired oven, the best option is a thin, perforated metal peel. My top recommendation is the Gi.Metal Perforated Peel because of its outstanding quality and performance.

If you make a purchease through this link, we earn a small commission at no additional cost to you.

I was first introduced to Gi.Metal peels in Naples a while back. All the pizzaiolos I talked to swore by this brand due to the quality. They are also light and easy to maneuver. These are pizza peels made for professional use, and it’s an investment in your pizza-making journey.

In addition to a perforated peel, I also highly recommend a turning peel.

Conclusion

In conclusion, whether you’re using a home oven, a small

- Is Your Pizza Dough Too Dry? Here is How to fix it! - June 10, 2024

- The Ultimate Guide to the Pizza Dough Windowpane Test - June 8, 2024

- The Ultimate Guide to Autolyse Pizza Dough - June 7, 2024